Sound booths were initially designed in the early 1900s as a space to get away from noisy settings in radio stations, film and TV locations, and phone booths. Thus the music and voice-over industries took advantage of this characteristic and refined them into the current sound booths we can find today.

A sound booth provides a noise-free space that can reduce up to 60 dB, and it’s necessarily used to record audio products for songs, musicians, voice-over narration for TV, radio, audiobooks, audio magazines, podcasts, audio courses, audio for video, and corporate commercial purposes.

What Is a Sound Booth Made Of

Sound booths or vocal booths are specially designed small rooms that reduce noise from coming in. They must be made with sound barrier materials (wood boards, mineral wool or fiberglass, mass loaded vinyl layers) and sound absorber materials (acoustic foam, acoustic blankets, or acoustic fabric).

To get the best sound insulation inside a sound booth, it’s necessary to identify first how much noise and specific sound frequencies affect the room where the sound booth will be located.

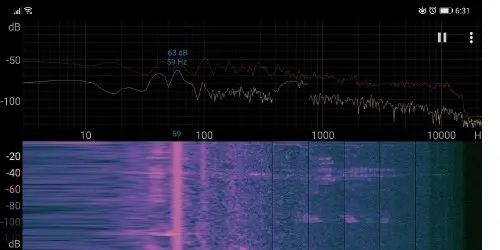

- For professional purposes, to know how much noise gets into the room, use a mobile phone app that works as a sound meter. If the noise gets above 45dB, the minimum sound insulation you need in your sound booth is that same value: 45 dB

- Then, use a spectrum analyzer mobile app. It will show you what specific frequencies are the more dominant. Knowing this is essential to make the right choice of sound barrier materials (mineral wool or fiberglass)

How Much Noise Does A Sound Booth Block?

A sound booth can block up to 60dB when the right sound barrier and sound absorber materials are used. First, identify how much noise you need to reduce in the room where you want to place the sound booth. The louder the noise, the more sound insulation materials and budget you will need.

The following examples show two types of wall ensembles and the amount of noise they can reduce (see all the details here)

If the level of unwanted sound near the sound booth is below 30dB, a standard booth can pass the test. If the level is above 40 dB, a double-wall sound booth is necessary.

Components of a Single Wall Sound Booth (Up to 30dB reduction)

- 3” total thickness

- Insulation material on walls

- Acoustic foam on inner walls, 60% absorption or more

- 1 layer of 1” wood board

- 2 panes ¼” laminated glass on window 16” x 30”

- ¾” door

- Ventilation system

Components of a Double Wall Sound Booth (Above 40dB reduction)

- 5 ¼” total thickness

- 5 panes of laminated glass on window 16” x 30”

- Door 3 ⅛”

- Insulation material on walls

- 2” Acoustic foam on inner walls 70 – 80% absorption

- 2 layers of 1” wood board

- Ventilation system

To reach 60dB noise reduction, add more layers of high-density sound barrier materials, such as 1.5 pounds mass loaded vinyl layers, extra Type X drywall, concrete, or brick walls. Leaving an air gap in between layers can also add sound insulation.

Sound Booth Shapes and Their Efficiency To Reduce Noise

In sound booths for musicians and singers, there must be a certain level of reflection or reverb. That fact can create some acoustic problems when the booth has parallel walls (square or rectangle shapes). The first strategy to fix this issue is never to make walls at 90° angles.

In sound booths for voice narration projects, the inner walls must be as absorbent as possible. Therefore, the frequencies that would be amplified and create unwanted sounds in a room with parallel walls with flat non-absorbent segments, wouldn’t be picked up by the condenser microphones in the booth.

Best Sound Barrier Materials for Sound Booths

Choosing the right materials to make a sound booth is the key factor to achieve the required sound insulation of a home or professional recording studio. Most of them are very good to reduce middle and high frequencies but do a very poor job with 150 Hz and below.

The best sound barrier materials that I use in my studios are:

- Soundproof Drywall boards See all the details of wood boards types here

- Mass Loaded Vinyl See How Much Noise Can Mass Loaded Vinyl Reduce

- Mineral wool batts See How Much Noise Can Mineral Wool and Fiberglass Reduce

- Fiberglass batts See How Much Noise Can Mineral Wool and Fiberglass Reduce

- Double glazing glass panes See How Much Noise Can Glass and Carpets Reduce

The higher the density of the material the better the sound insulation. Despite that, consider that adding up the noise reduction level (expressed in dB) of each layer of materials doesn’t work the same way as when adding whole numbers or decimals.

Wrong calculation

| ¼ Drywall Type X | ¼ Drywall Type X | Total Reduction | ||

| 20 dB | + | 20 dB | = | 40 dB |

Correct calculation

| ¼ Drywall Type X | ¼ Drywall Type X | Total Reduction | ||

| 20 dB | + | 20 dB | = | 33 dB |

| The first layer makes a 20dB reduction, but the second layer provides only 13dB |

This is the list of the best sound barrier material ensembles I use when I make sound booths for my customers:

| Wood Board Thickness | Noise reduction (dB) using a sound meter app | STC Noise reduction provided by a barrier material | Absorption coefficientNRC |

| 2 Soundproofing Drywall ⅝” layers PLUS 4” (or more) mineral wool | 60 dB | 60+ | 1.00 |

Best Sound Absorber Materials for Sound Booths

The materials with the highest NRC (Noise Reduction Coefficient) will provide the best sound absorption in a sound booth. All manufacturers include the percentage of noise reduction. Choose acoustic foam panels not lower than 60%. Auralex can reach up to 80%.

Use acoustic blankets to reinforce walls in small areas, which can be cheaper than installing more mineral wool or fiberglass.

These are my favorite sound absorber materials I like to use when I make sound booths for my customers:

- Acoustic foam See all the details here

- Acoustic Blankets (in soft wall portable sound booths)

Types of Sound Booths

The most common types of sound booths for voice-over projects:

- Fixed rigid wall or portable rigid wall booth (higher budgets)

- Portable soft wall booth (lower budgets)

Both are suitable for professional purposes, but the rigid wall type is the one that provides the best noise reduction.

Fixed Rigid Wall Vs Portable Rigid Wall Sound Booth

The only difference between them is that a set of 6 – 9 wheels is installed at the bottom of the booth, enabling its portability by just pushing the booth smoothly to the desired location.

The price range of both versions is about the same when you buy it from a manufacturer such as Whisper Room or VocalBooth ($5,600 – $6,200).

- If you make the sound booth to reduce 30dB or less, you may spend between $900 (with no ventilation) to $1300 (with insulated ventilation).

- For 40dB and more, you will need a budget between $1,800 to $2,400

Portable Soft Wall Sound Booth

This type of sound booth is very light to carry and easy to install. It uses PVC tubes and joints, plus a set of acoustic blankets. There are models with three walls or four walls. The sound absorption inside the booth is excellent, and the thickness of the material reduces a little amount of noise.

This type of sound booth is not designed to reduce noise (although it can do so but to a low scale) but to absorb reverb. Find more details on how to make a sound booth on a budget here.

How To Make A Sound Booth At Home

After reading this article now you have a very good idea of what are the right materials to use in a sound booth to comply with industry standards.

The following videos show how to build a rigidly fixed booth and a portable light sound booth:

The following recommendations can guide you to achieving the sound reduction level you need:

- Make sure to run the sound meter and spectrum analyzer apps after you set the wood boards and you have walls.

- Try playing music that has all the frequencies and make an extreme test setting the volume to get around 90dB

- That level will help you keep track of the noise reduction each barrier material makes, in case you want to add more layers, Repeat the extreme test after applying each layer

- Then, when the booth is finished, set the volume at 65 dB or the usual noise level that you get in the room you want to locate the booth, and run the apps again. Add an extra sound barrier layer if necessary